Project Description

Equipment Function:

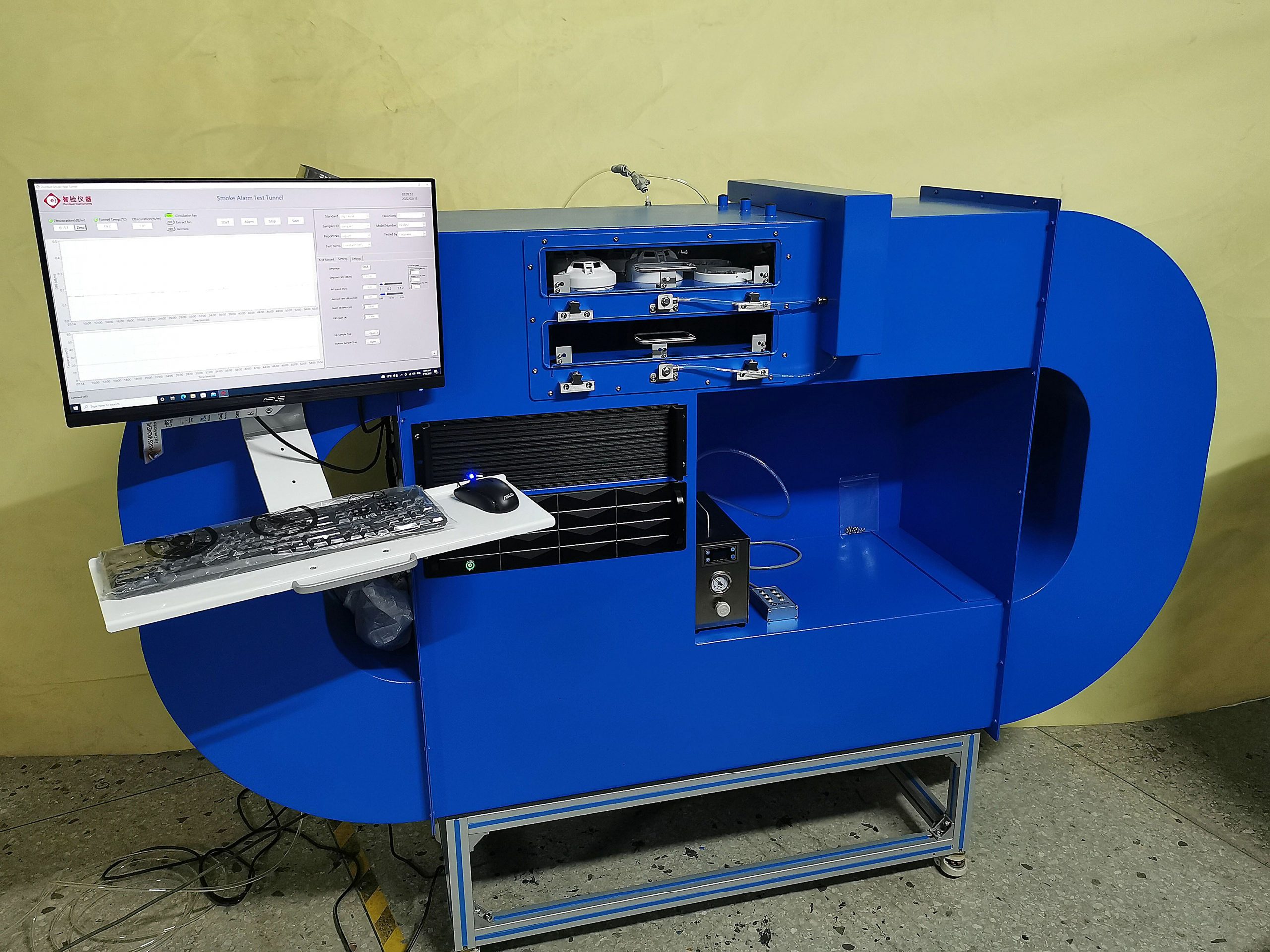

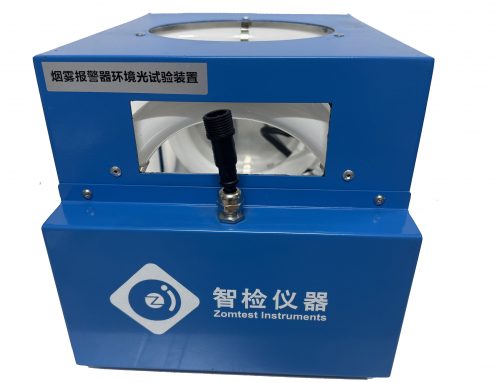

The smoke alarm production test tunnel was designed for batch test or calibration of sensitivity test of Smoke alarms or detectors. The basic work principle is compliance to EN 14604 and EN 54-7. It consist of test tunnel,aerosol generator, obscuration sensor, controller and computer. The obscuration meter was made of high quality electrical and optical components to ensure precision and stable reading. The two floor trays support by rodless air cylinders. They can extend and extract by press button or automatic control. The lids are fixed on tray and can close the opening in extended position and extraction position. The Zomtest Smoke Test Tunnel Software in English is able to set the air speed, aerosol buildup rate (ramp test), constant obs set value.

The aerosol concentration is controlled to set value by PID algorithm and can maintain the smoke density with +/-0.004dB/m in reading when door keep closing. After exchange of samples tray, the smoke density will drop and then resume to +/-0.005 range within half minute.

Specification :

- Model:ZNEN14604-18

- Power:220V AC 1KW

- Standards:EN14604,EN54-7, GB20517, GB4715

- Aerosol generator:Liquid paraffin , particle size distribution between 0.5µm~1.0µm,

- Optical smoke densitometer: transmitted light, wavelength 880nm~950nm, range: 0~2 dB/m,

- Test tunnel size: 3.1m x 0.5mx 1.1m.

- Test section size is 430mm x 270mm

- Wind speed: DC motor speed regulation, software setting speed, from 0 – 1.2 m/s

- Smoke rising rate: preset 0.005dB/m, can be set in the software.

- Send Obscuration value to com port via Modbus RTU. client can read the value via RS 485