Project Description

Equipment Function:

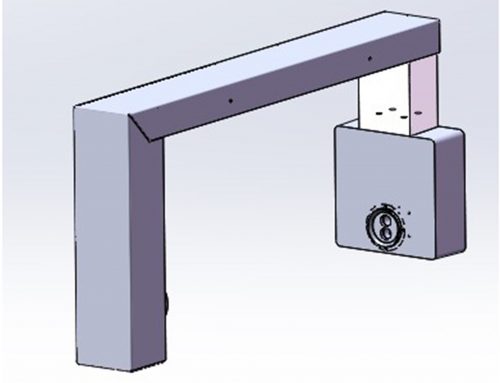

The smoke alarm production test tunnel is used for batch test or calibration smoke alarm and detector in production process. The main parts, aerosol generator and obscuration meter are fully same as standards smoke tunnel to ensure high reliable test result. The aerosol concentration in the smoke box is controlled by fine-tuned PID to maintain constant OBS of smoke in a narrow range of +/-0.004dB/m. The smoke alarm production test tunnel is installed on production assembly line. The alarms are placed on the conveyor belt and flow into the smoke box. After passing through the smoke box, check the status of the alarm. You can batch quickly test the smoke alarm or calibrate the sensitivity. The specially developed zomtest smoke test tunnel software carries out constant smoke control and continuous monitoring of smoke concentration. The speed of the conveyor belt shall be adjusted according to the response time of the sensor to improve the production efficiency.

Specification :

- Model:ZNAL-7

- Power:220V AC 1kW

- Aerosol generator:Liquid paraffin , particle size distribution between 0.5µm~1.0µm,

- Optical smoke densitometer: transmitted light, wavelength 880nm~950nm, range: 0~2 dB/m,

- Tunnel size: L1.4m x W0.49m x H0.7m. Customized width according to customer’s conveyor belt

- Wind speed: 0.2 to 0.8 m/s

- Smoke range:0.05 to 0.8 dB/m, set value±0.004dB/m