Project Description

Equipment Function:

The equipment is intended for gas alarm or Carbon monoxide alarm testing and calibration in mass production in advantage of its big volume. The equipment provides a sealed stainless-steel chamber with glass door for monitoring alarm status. The special designed big open door can close and secure easily without gas leakage. The volume of chamber and size of samples shelves are custom-made. It can contain about 60 alarms. The controller control high speed valve to inject quantitative high concentration gas into chamber and the gas stirred by circulating fan to get homogeneous test gas in certain concentration. That gas will be test gas for response test or threshold setting of gas alarm product. The circulating fan and porous plate are also specially arranged to get uniform test gas and avoid the high concentrating gas getting into alarm directly during gas injection.

On the top of chamber, the inlet and outlet and exhaust fan are controlled by PLC to exchange air in chamber.

Component:

- CH4/CO gas controller

- Adjust precision flow control valve manually

- Set the gas valve open time and inject gas with precision time control.

- The gas was injected in to chamber in short time and mix quickly. It is easy to count response time of alarm

- Control precision: +/-5ppm for CO

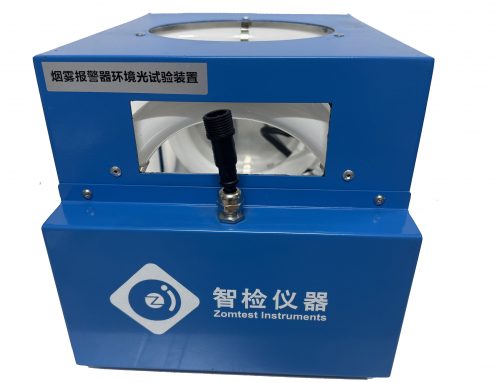

- CH4/CO alarm test chamber.

1)Stainless steel chamber with glass windows.

2)samples shelves, can fit with customized adaptor to connect with alarm for power supply or signal transmission

3)Chamber size: 0.8*0.65*1.0m

3.Gas analyzer, CO or CH4 shall be quoted separately