Project Description

Device features:

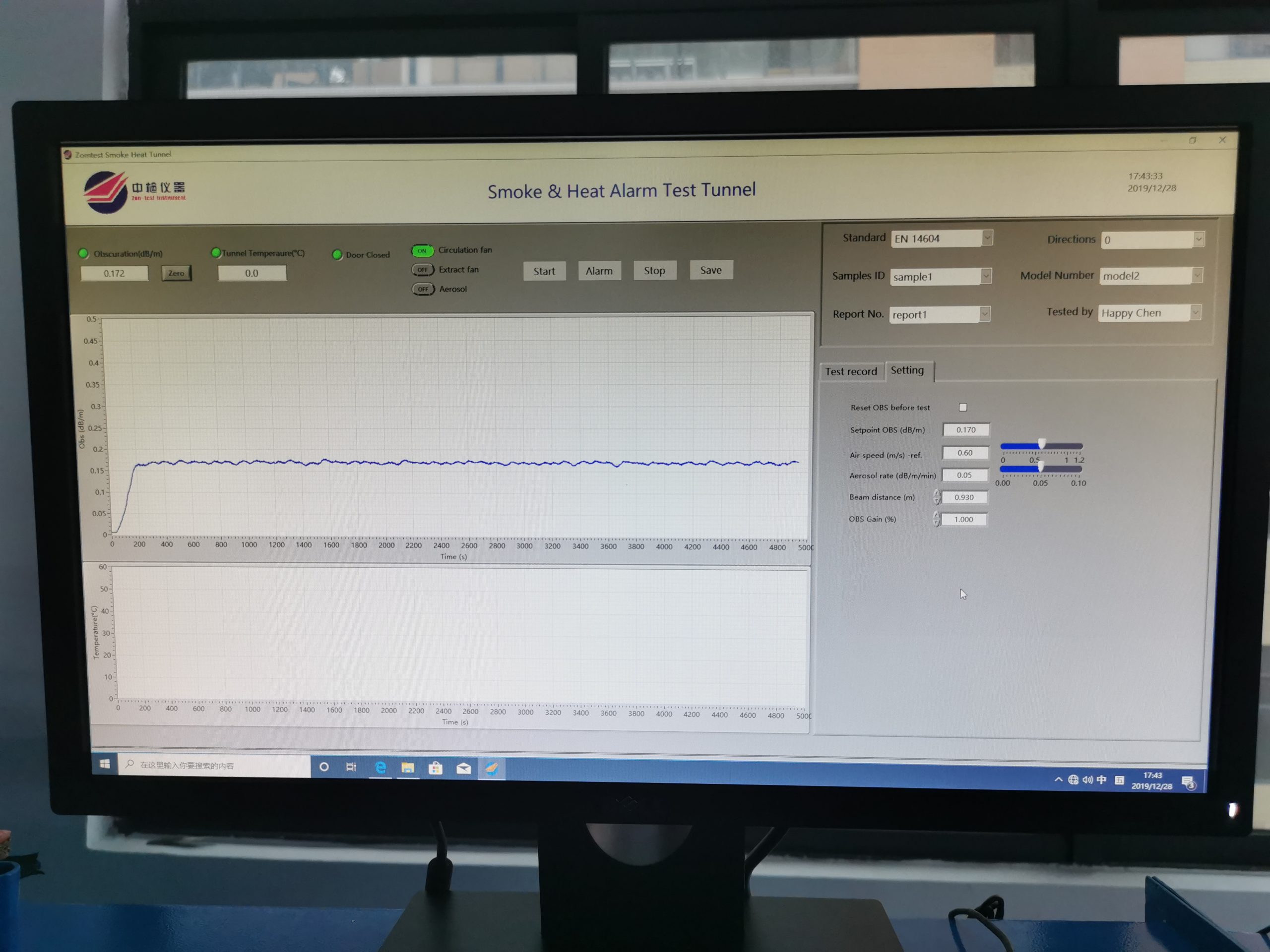

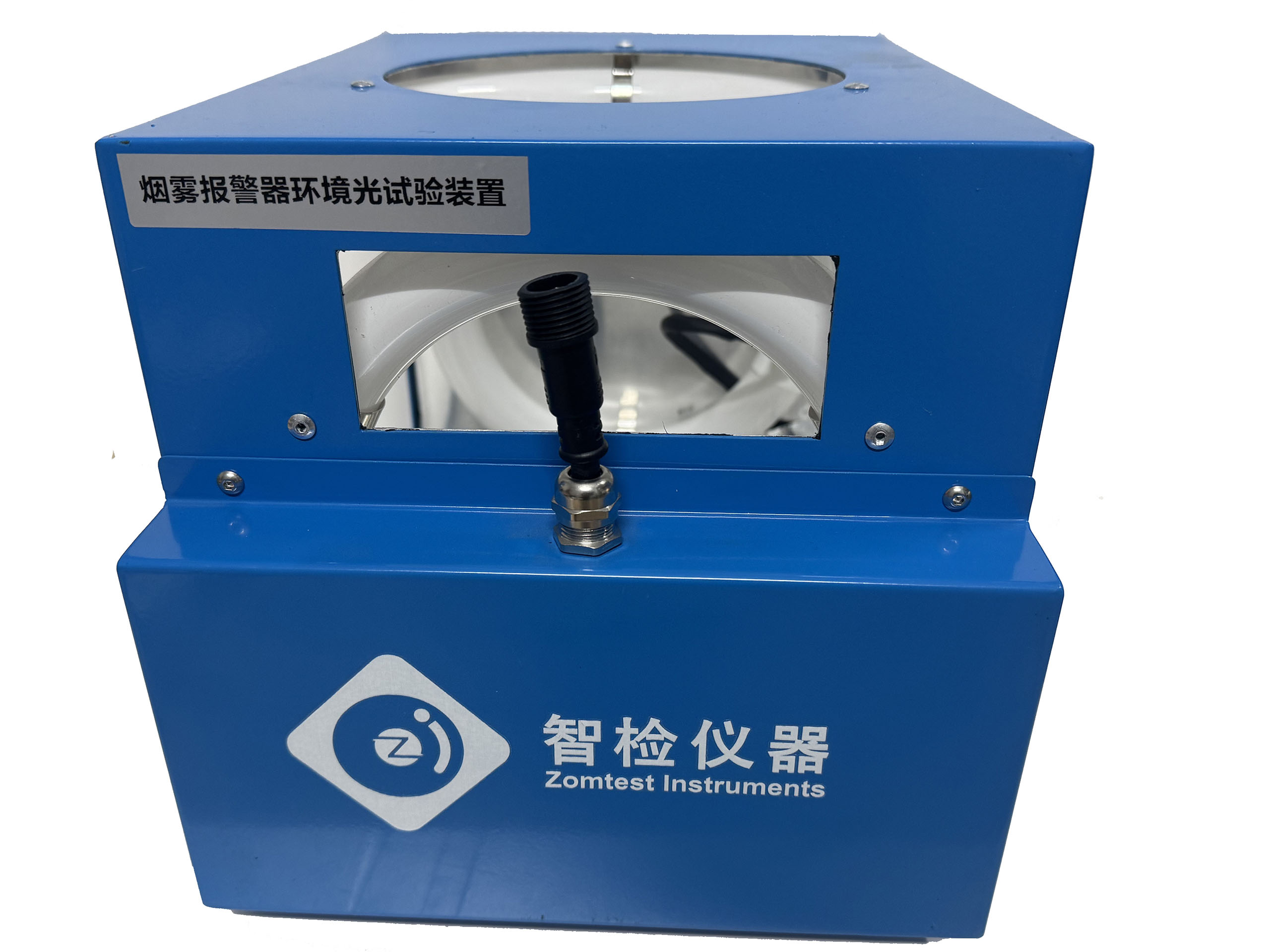

Production smoke boxes are developed from standard smoke boxes and are used for batch testing or calibration in the production of smoke alarms and detectors. The production of smoke box adopts the same smoke generator and smoke density meter as the standard smoke box, which is composed of the main body of the smoke box, smoke density meter and industrial control computer, in accordance with the standard specifications and parameters, with its own photoelectric sensor, which is used to detect the smoke concentration value in the smoke body, and adopts original imported components to ensure the accuracy and stability of the test. The smoke concentration in the smoke box is controlled by the intelligent PID control software, so that the smoke concentration dB/m value is kept within a constant range. Smoke alarms can be quickly placed in batches for batch detection, or sensitivity calibration. The specially developed Zontest Smoke Test Tunnel software continuously monitors the smoke concentration.

The production of smoke boxes can also control the smoke rise rate, which can be used for sampling, R&D testing.

Production cigarette boxes can be customized with different pallets or conveyor belts according to customer requirements.

Equipment parameters:

1) Model: ZNEN14604-2

2) Power supply: 220V AC power: 5 kW

3) Standard: EN14604, EN54-7, GB20517, GB4715

4) Smoke generator: light paraffin water, particle size distribution between 0.5um~1.0um,

5) Optical smoke density meter: transmitted light, wavelength 880nm~950nm, range: 0~2 dB/m,

6) Box size: 2.2m x 0.5m x 1.1m. Flue cross-sectional size 430mm x 270mm

7) Wind speed: DC motor speed regulation, software set speed

8) Smoke rate: 0.005dB/m by default, which can be set in the software